Inside Our Anping Facility

Where Precision Meets Production. See how we weave 5,000+ rolls of high-quality mesh every month.

Premium Wire Sourcing & IQC

Great mesh starts with great wire. We procure high-precision stainless steel wire directly from top-tier certified steel mills.We don’t just rely on supplier certificates; we verify. Upon arrival, our Incoming Quality Control (IQC) team inspects every batch. We conduct PMI testing to confirm the material grade (304/316L) and strictly measure the wire diameter

tolerance and tensile strength. Only wires that pass these tests are allowed onto our looms.

Advanced Weaving Looms

Our weaving workshop is the heart of Songsen. Equipped with 100+ sets of looms, we operate 24/7.Whether it’s a standard plain weave or a complex twill dutch weave, our automated machinery ensures consistent mesh aperture and a flat surface, free from weaving defects.

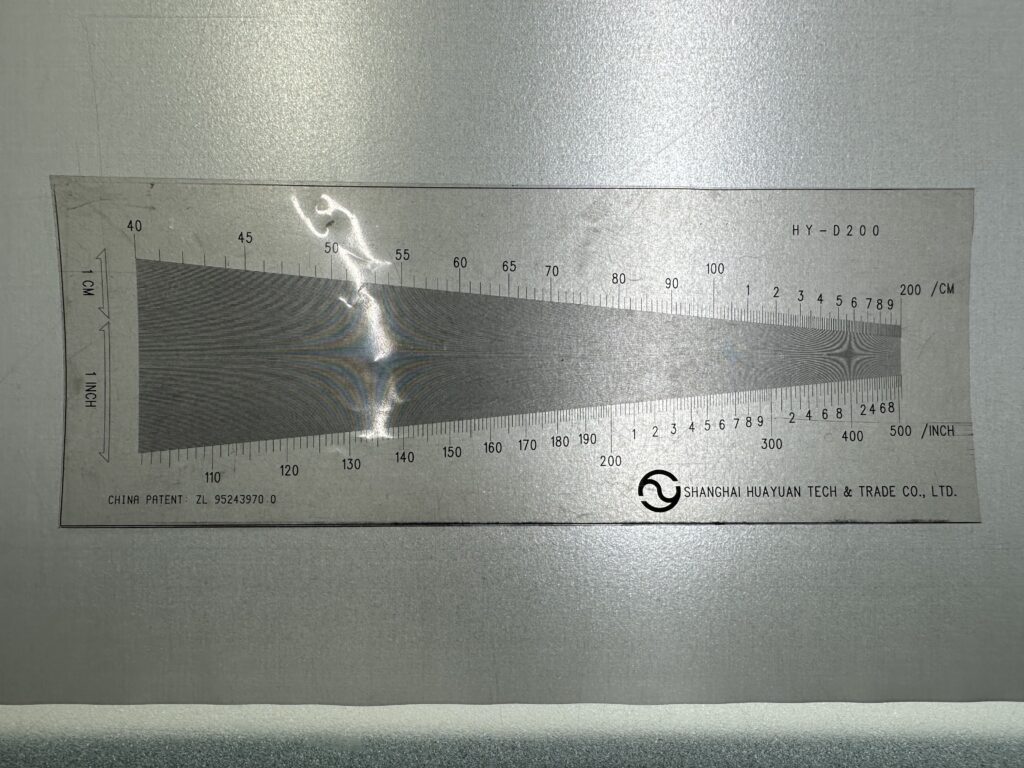

Strict Quality Inspection

We have a zero-tolerance policy for defects. Our QC team performs visual inspections on a backlit table for every roll.We measure mesh count, wire diameter, and thickness. Only products that pass our 10-point checklist receive a ‘Qualified’ stamp and proceed to packaging.

Warehousing & Logistics

Your order is safe with us. Our 5,000 sqm warehouse ensures ample space for stock items.We use standard export packaging: waterproof paper, plastic film, and fumigation-free wooden crates. Our loading team is experienced in maximizing container space while ensuring goods are secure for sea transport.

See It In Action

We welcome clients from all over the world to visit our facility.

Can’t travel? We also offer live video factory audits via WhatsApp.

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.